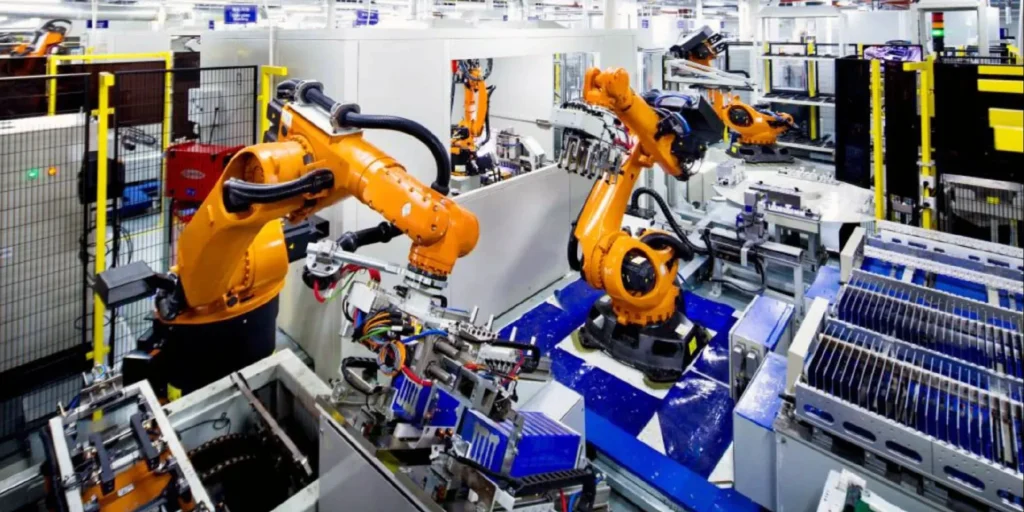

Tesla is reputed to planning another battery processing plant to deliver LFP cells in the US with China’s CATL, the world’s greatest battery producer.

The chemistry mix and materials of batteries in electric vehicles have become a hot topic in recent years, particularly with key ingredients such as nickel and cobalt being in short supply, and the price of lithium going through the roof.

That is on the rear of US Inflation Reduction Act (IRA) that gives a full $US7,500 tax reduction to US purchasers that buy an EV with US-constructed batteries.

Throughout the course of recent years, CEO Elon Musk has said on various occasions that Tesla intends to move more electric vehicles to LFP batteries to beat nickel and cobalt supply concerns.

This supposed LFP battery manufacturing plant will permit Tesla’s Model 3 single-engine, RWD vehicles to be qualified for the full tax break further speeding up the take-up of EVs in the nation by making them more reasonable.

Nonetheless, they have further developed enough as of late that it currently seems OK to involve sans cobalt batteries in lower-end and more limited range vehicles. It additionally opens up the creation of battery cells with other, more energy-thick sciences to deliver long-range vehicles

The central concern is that LFP battery cell manufacturing is right now as a rule moved into China. Consequently, it makes a strategic issue for electric vehicles delivered in different business sectors.

Moreover, in the US, it makes an issue for automakers attempting to profit the new government tax reduction for electric vehicles, which expects that the batteries of electric vehicles be delivered in North America for purchasers to get the full $7,500 credit. It spurs an interest to carry LFP creation in North America.

LFP batteries don’t contain supply-compelled minerals like Nickel and Cobalt which are by and large more costly than Iron Phosphate based batteries.

The primary drawback of the LFP batteries is the lower energy density, which makes them less productive and gives a lower range in some EV applications. Because of the optimal design or aerodynamics and other effectiveness acquires in Tesla’s vehicles, the LFP batteries don’t have as a very remarkable drawback over Nickel and Cobalt batteries.

The least reach being presented in Tesla vehicles in Australia is in the LFP battery-prepared Model Y vehicle is 455 km on the WLTP cycle. That is entirely decent for a medium sized SUV with thousands conveyed onto Australian streets over the most recent 9 months.

Tesla money involves the LFP batteries from CATL in its standard reach RWD vehicles, including those transported to Australia. These batteries are likewise more sturdy with Tesla prescribing energizing to 100 percent.

This incorporates the Tesla Model 3 and Tesla Model Y RWD variations which end up being the most reasonable EVs from Tesla.

Ford as of late likewise declared plans for building a $US3.5 billion production line into the territory of Michigan which will likewise be building LFP battery cells. This is by all accounts a pattern numerous US makers are beginning to consider.

More locally, Ford has recently uncovered insights concerning the forthcoming send off of the Horse Mach-E which will have a solitary engine RWD variation. The Mach-E Select will incorporate a 71 kWh Lithium Iron Phosphate (LFP) battery load with up to 470 km to reach.

CATL likewise as of late reported the manufacturing plans for M3P batteries will convey a higher reach in ongoing EVs.